| Item Master Edit is used to create items that will be tracked in the inventory system. Each item will have a description, a UPC Code (used in bar coding), last received and last ordered dates, on hand quantity, on order quantity, and on reserve quantity, vendor ordered from, and a comment.

Each item can have one or more locations, and the on hand quantities will be tracked by each location. When items are added to inventory, the quantity can be entered here and the on hand quantity will be increased.

|

Click image for larger view

|

|

A scanner can be used to remove items from inventory simply by scanning the bar code of the item, assuming the bar code contains the UPC code of the item. Each scan indicates one unit being removed from inventory. This screen can be modified to include a quantity field so the item bar code is scanned, then a quantity entered showing how much was removed from inventory. |

| The scanner is synced to the pc and the data is uploaded into the system using this screen. The on hand quantities are reduced for each bar code scanned. A transaction is created for each item and each scan. |

Click image for larger view

|

Click image for larger view

|

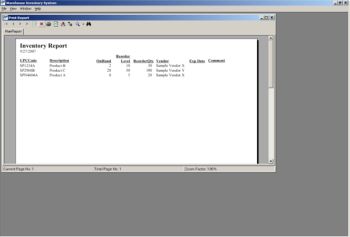

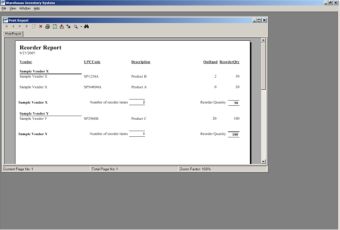

A report can be run at any time that shows the current on hand quantity, the reorder level, and the reorder quantity. This report shows all items and what their current quantities are.

|

| A report can be run at any time that shows the items that need to be reordered. All items that the on hand quantity is less than the reorder quantity. It groups the items by vendor, and shows the reorder quantity so an order can be created for each vendor.

|

Click image for larger view

|